Table of Contents

- What Is Supplier Data Management?

- Enhancing Procurement Efficiency

- Effective Supplier Data Management for Streamlined Procurement

- Challenges in Supplier Data Management

- Benefits of Supplier Data Management Solutions

- Improving Vendor Relationships

- Supply Chain Risk Management

- Best Practices for a Successful Supplier Data Management Strategy

- Improving Cost Savings and Operational Efficiency

- Real World Example: Large Beverage Distributor

- Conclusion

- Additional Resources

What Is Supplier Data Management?

Supplier data management is the practice of collecting, organizing and maintaining critical supplier information, which helps ensure smooth procurement operations. Good supplier management involves keeping track of supplier profiles, contact information, performance metrics, compliance documents (including information related to environmental, social and governance [ESG] issues) and other important data.

Businesses using a centralized supplier data management solution can benefit from real-time updates, consistent data and improved operational efficiency. Effective supplier data management can lead to cost savings, better compliance and a competitive advantage in a dynamic business landscape.

How Can Supplier Data Management Lead To Enhanced Procurement Efficiency?

For businesses that depend on suppliers, managing supplier data is incredibly important. Companies can improve procurement processes, data accuracy and vendor relationships by having the right supplier information. This article will explain why supplier data management is important and how it streamlines procurement and addresses common chalenges. Additionally, it will review the benefits of using centralized systems.

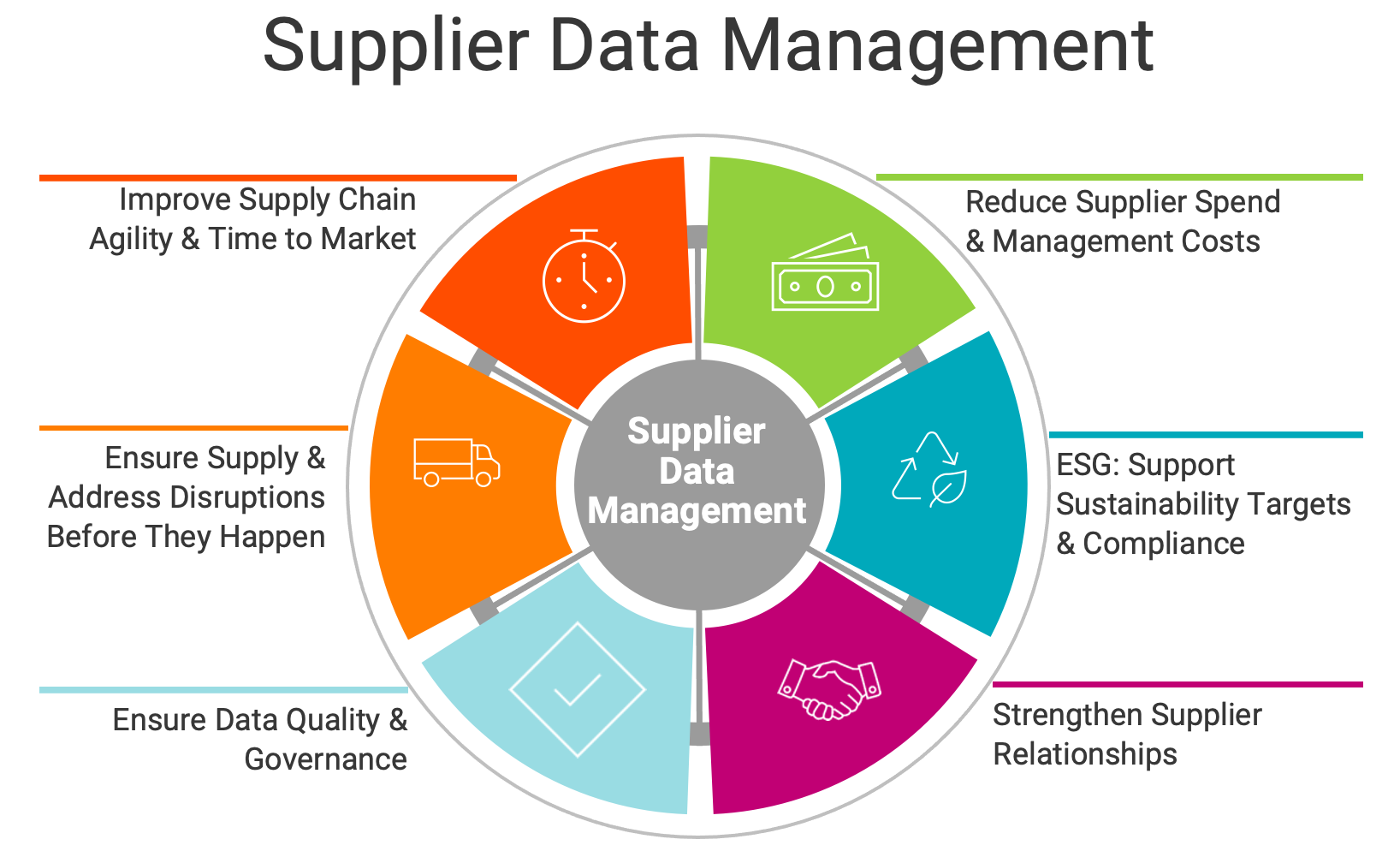

Supplier data management can help you improve supply chain visibility, gain operational efficiencies and increase agility for supplier onboarding and time to market.

For businesses, effective supplier data management is vital for the following reasons:

- Data accuracy. It is crucial to have accurate supplier data to avoid mistakes and problems with the supply chain. This will help ensure that the company works with the correct suppliers and that orders are fulfilled without issues.

- Enhanced decision-making. Businesses need accurate supplier information to decide where to source products, how much to pay and which vendors to choose.

- Risk mitigation. Organizations can identify possible supplier risks and reduce their effect on the supply chain using effective supplier data management.

Supplier Data Management Benefits

How Can Effective Supplier Data Management Streamline Procurement Processes?

Effective supplier data management streamlines procurement processes in the following ways:

- Faster supplier onboarding. Proper SDM enables swift supplier onboarding, reducing delays in sourcing and production.

- Streamlined communication. Access to up-to-date supplier information helps to ensure smooth communication and collaboration. This can lead to quicker issue resolution.

- Automated workflows. Automating repetitive tasks like purchase order processing and invoice validation can save time and effort. Centralized supplier data management systems can help with this.

- Spend analysis. Analyzing supplier data can help identify spending patterns. This information can be used to source materials and optimize costs strategically.

Key Challenges in Managing Supplier Data and How to Overcome Them

Managing supplier data can be challenging due to various factors, including:

- Data silos. Data from suppliers may be stored in different formats and systems across other departments. This can cause the data to be siloed and fragmented.

- Inaccurate data. Depending on incomplete or outdated supplier information can lead to incorrect decisions and disruptions in the supply chain.

- Data security. Maintaining data security and compliance is critical to safeguarding sensitive supplier information.

To overcome these challenges, businesses should invest in a robust supplier management system that centralizes data, implements data quality checks and establishes strong security measures.

Benefits of a Supplier Master Data Management Solution

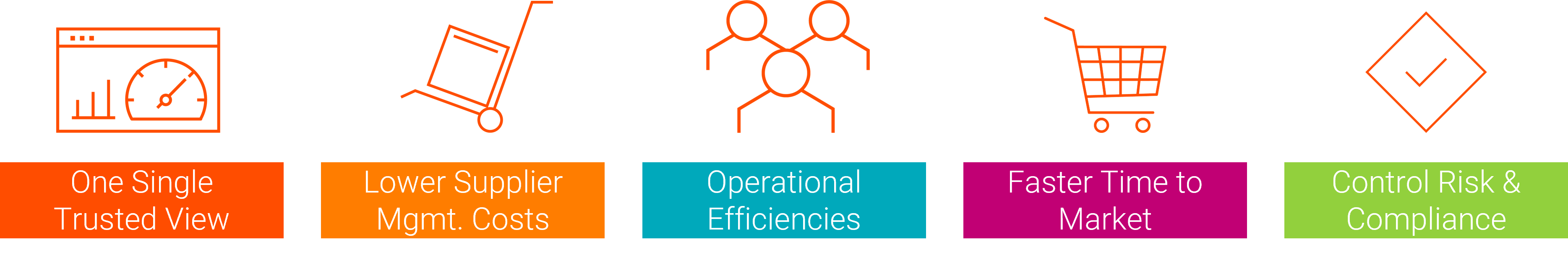

Managing supplier information with a 360-degree view is more than a methodology or technology solution. It’s a discipline, a process and a cultural mindset that helps you do five essential things:

Benefits of 360° Supplier Information Management

Achieve a 360-Degree View of Supplier Data: Process data from source systems and create a 360-degree view of virtually all supplier data to gain a trusted understanding of supplier relationships.

Reduce Costs: Having a reliable view of suppliers that buying teams and applications can access reduces supplier information management costs. Some companies save millions of dollars annually by automating and streamlining supplier management. This approach also allows procurement and sourcing teams to see the total amount spent on each supplier. Armed with this information, they can negotiate better corporate discounts, pricing and payment terms, ultimately reducing sourcing costs.

Operational Efficiencies: Collaboration between departments involved in supplier management becomes more efficient with role- and task-based workflows. You can streamline your supplier management and supply chain teams with the ability to monitor supplier performance and get answers to supply chain questions such as delivery times and quality.

Faster Time to Market: Automating processes can help companies become more agile and speed up their time to market. This can include reducing the time it takes to onboard new products or services.

Control Risk and Compliance: To help finance, legal and supplier relationship management teams monitor and analyze their suppliers' risk and compliance, it's essential to use accurate and trustworthy supplier data. This means fueling supplier-facing applications, business intelligence tools and analytics programs with up-to-date information.

Adopting a centralized approach to supplier data — creating a supplier 360 with master data management — offers several advantages, including:

- Data consistency. A centralized system ensures consistent and standardized supplier data across the organization.

- Efficient collaboration. Teams from different departments can access accurate data, improving collaboration and decision-making.

- Real-time updates. Changes to supplier information are immediately reflected across the system, reducing data discrepancies.

- Vendor performance tracking. A centralized system enables businesses to track and evaluate supplier performance. This supports better supplier relationship management.

Supplier Data Management and Improved Vendor Relationships

Effective supplier data management plays a crucial role in fostering better relationships with vendors through:

- Transparency. Clear and accurate supplier data promotes transparency, enhancing trust between businesses and their suppliers.

- Effective communication. Access to real-time supplier data facilitates open communication, enabling businesses and suppliers to address issues promptly.

- Incentivized performance. Supplier performance tracking allows businesses to recognize and incentivize top-performing vendors, creating mutually beneficial partnerships.

- A focus on supplier experience (SX). Many companies are improving their interactions with suppliers to boost their overall performance. According to Deloitte, 87% of businesses are currently working on enhancing their supplier onboarding and engagement processes.1

Supplier Data Management in Supply Chain Risk Management

Supplier data management is closely linked to supply chain risk management strategies. Deloitte's research indicates that 82% of organizations now incorporate supplier risk assessments into their data management processes, aiming to identify and mitigate potential risks associated with suppliers.2

- Risk Identification: Proper supplier data management enables businesses to identify potential risks related to suppliers, such as financial instability or geopolitical uncertainties.

- Contingency Planning: Understanding supplier dependencies helps organizations develop effective contingency plans to mitigate supply chain disruptions.

- Compliance Monitoring: Supplier data management ensures suppliers adhere to regulatory and compliance requirements, reducing legal and reputational risks.

- Enhancing Compliance with Regulatory Requirements and ESG Standards: Supplier data management significantly contributes to regulatory compliance.

- Data Accuracy: Accurate supplier information helps organizations comply with reporting and auditing requirements.

- Data Security: Implementing data security measures ensures compliance with data protection regulations.

At the same time, ESG considerations are increasingly influencing supplier selection and management. Deloitte's survey reveals that 63% of organizations now assess suppliers based on their ESG performance, aligning with their sustainability goals and values.3 Regulatory mandates are formalizing these requirements—for example, Digital Product Passports require manufacturers to collect and verify ESG data from multi-tier suppliers to document product lifecycles for batteries, textiles, and electronics sold in the EU.

Supplier diversity is also emerging as a significant consideration in supplier data management. According to Deloitte, 71% of companies actively track and report on supplier diversity metrics to promote inclusive procurement practices and enhance supplier relationships.4

Best Practices for Implementing a Successful Supplier Data Management Strategy

To implement an effective supplier data management strategy, consider the following best practices:

- Data standardization: Establish standardized data formats and definitions for consistent supplier information.

- Regular data updates: Maintain a schedule for updating supplier data to ensure accuracy and relevancy.

- Data governance: Establish clear roles and responsibilities for data management within the organization.

- Supplier onboarding process: Implement a streamlined onboarding process to collect necessary supplier data efficiently. Unilever, a leading global consumer goods company, reduced supplier onboarding time by 80% using Informatica Supplier 360 for supplier data management.

- Data quality checks: Regularly conduct data quality checks to identify and correct inaccuracies.

- Shift towards cloud-based solutions: Cloud-based supplier data management solutions are gaining traction due to their scalability, accessibility and cost-effectiveness. Learn more about cloud-native supplier data management solutions.

How Supplier Data Management Improves Cost Savings and Operational Efficiency

Implementing a robust supplier data management system leads to cost savings and operational efficiency thanks to:

- Reduced errors and the need for re-work: Accurate supplier data reduces errors in procurement, minimizing the need for re-work and associated costs.

- Negotiation leverage: Informed sourcing decisions based on data analysis give businesses stronger negotiation positions with suppliers.

- Resource optimization: Automated workflows and centralized data reduce manual efforts, optimizing resource allocation.

Successful Beverage Distributor Transforms with Supplier Data Management

A leading beverage distributor in North America achieved remarkable growth by optimizing supplier data management capabilities. By centralizing the onboarding of supplier data and enhancing data governance, they established consistency across 30+ markets.

Efficient data governance. With a solid data governance foundation, the distributor established a reliable "single source of truth" for supplier, product and customer domains. This enabled seamless reconciliation across multiple ERP systems and introduced data onboarding and enrichment automation.

Informatica Supplier 360. The distributor consolidated supplier data from five ERP systems, paving the way for future ERP consolidation while maintaining data integrity.

Dun and Bradstreet Enrichment. The distributor improved data quality and streamlined workflows using Dun and Bradstreet enrichment in the supplier portal.

Automated Workflows. Informatica's automated workflow facilitated approval processes and state licensing validation based on market and state regulations.

Empowering Growth. The distributor extended Supplier 360 to include the product domain, offering valuable insights into their business ecosystem.

Remarkable Outcomes. With strategic supplier data management, this beverage distributor achieved exceptional growth and efficiency, setting a course for continued success:

- 50% faster supplier and market onboarding

- Automated routing for efficiency and compliance

- Wholistic reporting for critical suppliers

- Cross-market and channel performance reporting

- Consistent and high-quality supplier data

Supplier Data Management Is Critical to Successful Procurement Operations

To stay competitive in today's business environment, businesses must manage their suppliers efficiently. This can be done by adopting effective supplier data management practices and centralized supplier data management systems. These practices can help companies to streamline procurement processes, improve vendor relationships, reduce risks and save costs while increasing operational efficiency. Investing in robust supplier data management is critical to fostering successful supplier collaborations.

Additional Resources

To learn more about how effective supplier data and supplier information management can help you achieve your business goals, check out the following resources:

Read 5 Ways to Optimize Supply Chain Management.

Learn How to Build a Winning Business Case for Mastering Supplier Data.

Download this brochure to find out how to get a trusted view of your supplier data.

Discover how you can master and govern supplier data.