Table of Contents

What is supplier relationship management?

Why managing supplier relationships matters

Challenges in Supplier Relationship Management

Best practices for supplier relationship management

Tips for better supplier relationship management

Supplier relationship management success story

Additional Resources

Today’s global supply chains face multiple unprecedented challenges, including increasing market volatility, uncertain political environments, global inflation, impacts of the climate, labor shortages and an ever-changing economic environment. These challenges make supplier relationship management more important than ever. Healthy supplier relationships reduce costs, ensure agility and maintain supply chain continuity. Armed with more effective strategies, organizations are prioritizing how they manage their supplier relationships.

What Is Supplier Relationship Management?

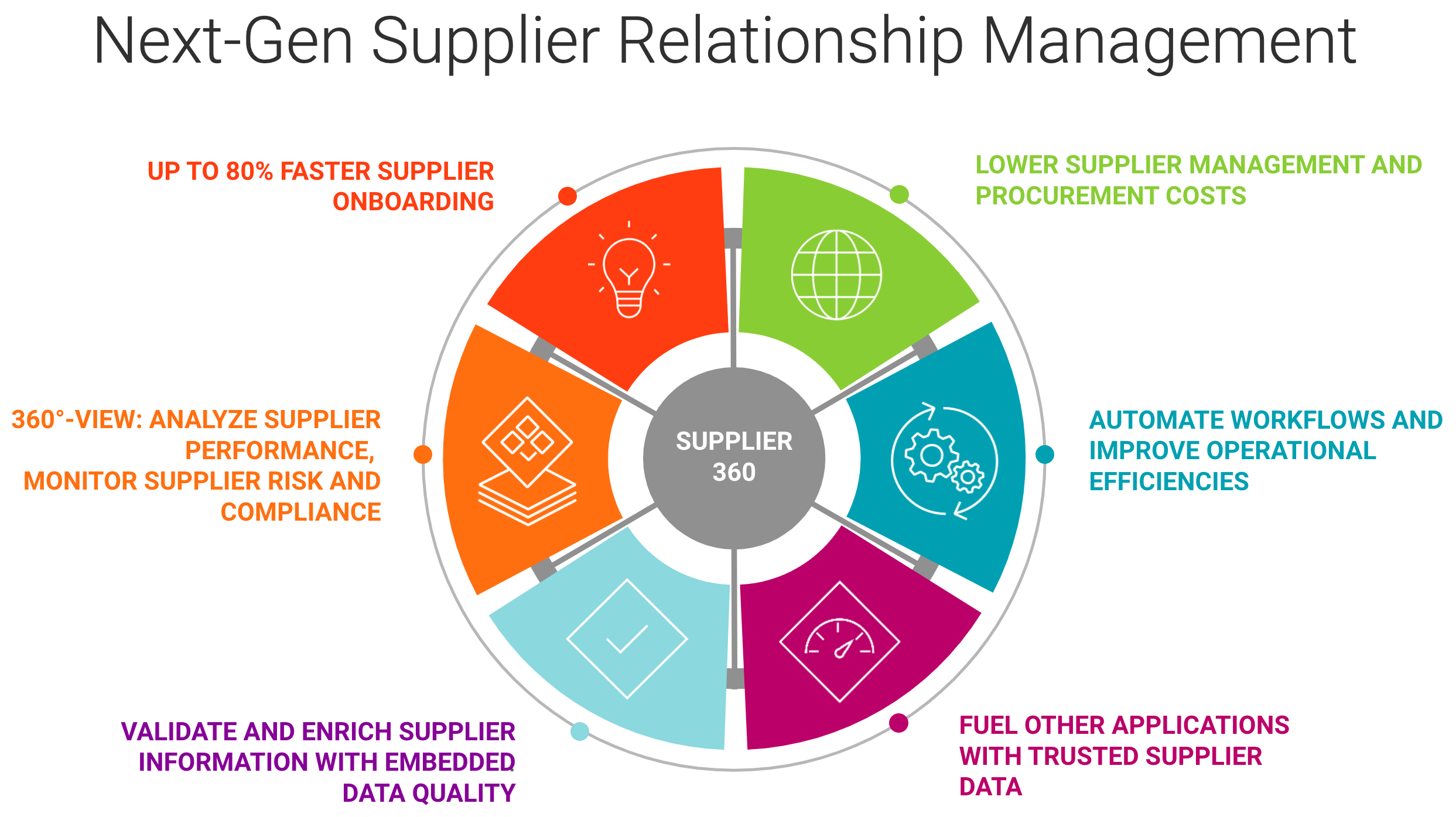

Supplier relationship management is a structured approach to effectively managing all supplier relationships. A good strategy for supplier relationship management helps you maximize the business value of your supplier interactions. Relationships can be well-maintained with the aid of vendor data (e.g. contact information, products, and services), lifecycle management, workflows (e.g. onboarding), hierarchies, risk, performance and compliance.

Why Supplier Relationship Management Should Be a Priority

Good supplier relationship management delivers visibility throughout your supply chain. This visibility for your supplier and sub-suppliers can reduce risk to your business. If you don’t have a strategy in place, it can lead to a variety of undesirable outcomes, such as:

- Wasted resources

- A lack of timely business insights

- High procurement costs

- Slow time to market

- Missed opportunities

- Negative brand perception

- Compliance issues

The right supplier relationship management solution can reduce the time it takes for you to onboard a new supplier — allowing you to get a new supplier in your system in just a few days instead of several weeks. And better supplier relationship management can help to ensure that you know whether your suppliers and sub-suppliers comply with industry and sustainability standards.

Top Supplier Relationship Management Challenges

Whether you’re a supply chain or procurement executive in manufacturing, distribution or retail, these pain points are pretty universal. If you’re sourcing products or services from hundreds (or even thousands) of vendors, you need to address the following challenges related to supplier relationship management:

- Gaining a trusted view for all vendors

Procurement and supply chain executives struggle to get a trusted view of all their suppliers across the enterprise. They also need easy access to supplier information. In fact, only 50% of procurement leaders have high or extremely high visibility into their tier-1 suppliers.1 Meanwhile, 90% of organizations rate their visibility into their extended supply networks as moderate to very low.2

- Improving operational efficiency

Most companies don’t use the right tools for automating and streamlining supplier relationship management. Or they rely on improvised Microsoft Office tools.3 These manual and largely ineffective methods cause redundancies in workload that hinder productivity.

- Reducing procurement costs with strategic suppliers

93% chief procurement officers (CPOs) say cost reduction is critical for their organization.4 Procurement would be better positioned to reduce costs negotiating corporate pricing, terms and discounts with a 360-degree view of all supplier relationships across the organization.

- Accelerating time to market

Delays in time to market can affect competitive advantage and revenue. Just imagine the opportunities you may miss if it takes you months to onboard a supplier. It’s no surprise that more than two-thirds of CPOs cite improving and automating procurement processes as a top priority.5

Assessing supplier risk and compliance is paramount. 93% CPOs rated risk reduction as a top priority for their organization.

Supplier Relationship Management Best Practices

So, given the challenges above, what can you do to establish successful supplier relationship management at your company? Consider these best practices:

- Start with complete, high-quality and up-to-date supplier data.

- Make sure you have a 360-degree view of the supplier network and all supplier information.

- Build and maintain your supplier relationship management solution on accurate supplier master data. Use a master data management solution as a foundation with embedded data quality checks and data enrichment options.

- Get management buy-in. Use the list above to communicate how supplier relationship management can significantly contribute to important business goals.

5 Tips You Can Use Now for Better Supplier Relationship Management

There are several ways supplier relationship management can help you achieve business goals. Here are five tips that supply chain and procurement executives can start with today.

Tip 1. Reduce Procurement Costs With a Holistic, Trusted, Single View of Supplier Data

Use a master data-fueled 360 application to create a holistic, trusted, single view of supplier data and make it available to all buying teams. Providing all business-critical supplier and product information significantly helps cut supplier information management costs.

Some companies save millions of dollars per year just by streamlining and automating their supplier management. When procurement and sourcing teams gain visibility into the total spend per supplier, they can negotiate more favorable corporate discounts, pricing and payment terms to further reduce sourcing costs.

Tip 2. Mitigate Supply Risk By Centrally Managing Governed and Relevant Supplier Data

By centrally managing governed and relevant supplier data across the entire business, supplier management can access a 360-degree view of all supplier data and gain a better understanding of supplier relationships, including sub-suppliers.

Create a 360-degree view of all supplier information to identify critical suppliers and work jointly on developing supply market insight — at and beyond the first tier. You can then make sure that all supplier-facing applications, business intelligence tools and analytics programs have trusted, governed, up-to-date supplier data. This helps finance, legal and supplier relationship management teams to monitor and makes it easier to analyze suppliers’ risk and compliance.

Tip 3. Improve Time to Market and Enter New Markets

Improve time to market by accelerating supplier onboarding with automated processes. Supplier relationship management solutions allow you to significantly increase agility and speed up time to market. Reducing the time to onboard a supplier from weeks to days also creates opportunities in new markets and makes it easier to partner with suppliers who already have a strong presence, capability and track record in that market.

Tip 4. Improve Brand Image and Ensure Compliance

Sustainability, end-to-end supply chain transparency and ESG reporting represent more than prerequisites for good brand reputation. Quite often, they’re also required for regulatory compliance. You want to be able to monitor how well your suppliers adhere to industry standards and your sustainability requirements to help improve your brand image and ensure compliance.

Tip 5. Improve Operational Efficiencies

A master-data-fueled supplier information management solution can help you automate supplier-related workflows and improve operational efficiencies. This can help all departments involved in supplier management to collaborate more efficiently. Meanwhile, supply chain teams can streamline the way they manage suppliers’ lifecycles, easily monitor supplier performance and get answers to key supply chain questions such as: “Do they deliver on time?” and “Is this the right quality and quantity?”

A 360-degree view of suppliers is the foundation for successful supplier relationship management

Supplier relationship management success story: Onboarding in days, not weeks

To drive business growth, a leading multinational consumer goods company wanted to improve the quality and accelerate the time it took to create and master product, customer, and supplier data. As part of a broader digital transformation, they invested in a master data management solution from Informatica, including Supplier 360 for supplier relationship management.

Today, they are managing relationships with suppliers in over 80 countries. They have significantly improved their supplier data quality and visibility into their supplier ecosystem.

During COVID-19 in 2020, they reduced the time they needed to onboard new suppliers from 45+ days to only a few days. They’ve also measurably improved the quality of their supplier data, getting it right the first time and reducing their workload to manage supplier data as a result. They’ve also introduced the right levels of controls and authorizations to help with their internal audit requirements.

Additional Resources

To learn more about supplier relationship management and how effective supplier data and supplier information management can help you achieve your business goals, check out the following:

Read this blog to understand how you can strategically manage supplier relationships.

See the 5 ways you can optimize your supply chain.

Download this brochure to learn how you can get a trusted view of all your data with supplier information management.

Discover how you can master and govern supplier data.

[1]https://www.pwc.com/us/en/library/covid-19/pwc-covid-19-cfo-pulse-survey.html

[2]https://www2.deloitte.com/content/dam/Deloitte/us/Documents/process-and-operations/2020-chief-procurement-officer-flash-survey.pdf

[3]https://www.bain.com/about/media-center/press-releases/2018/digital-procurement-report-2018/

[4]https://www2.deloitte.com/content/dam/insights/us/articles/2019_CPO-Survey/6267_CPO-Survey-Collection-Page/DI_CPO-Survey.pdf

[5]https://www.bain.com/about/media-center/press-releases/2018/digital-procurement-report-2018/