Increasing Business Resiliency With Supply Chain Mapping

Although the Covid-19 pandemic has heavily disrupted most industries, the disruption has not been uniform: while some have suffered, others have grown. One area that has been particularly impacted is supply chain management. It has become much harder for companies to get accurate demand forecasts following traditional methods due to lockdowns, changes in customer behaviors, and disruptions to the supply chain.

This has caused many companies to take more of a "just in case" rather than "just in time" approach when dealing with their supply chains. Companies have needed to quickly scale up and scale down their operations to meet the unpredictable demand. But how can companies do this without creating expensive stockpiles of supplies and inventory? Do companies need to sacrifice leanness to increase reliability? That is not an option for many companies as both risk reduction and cost reduction continue to be important—and sometimes conflicting—priorities.

Reliability does not necessarily need to come at the cost of holding expensive inventory. It can also come through deeper understanding of the end-to-end supply chain. According the Deloitte Annual global Chief Procurement Officer (CPO) survey, 65% of procurement leaders have limited or no visibility beyond their tier 1 suppliers.

A great way for an organization to improve visibility into its end-to-end supply chain is supply chain mapping. Supply chain mapping is the process of mapping primary and related supplier relationships for better transparency. Depending on the criticality of a supplier, any number of levels of sub-suppliers can be mapped out. By being able to visualize and navigate supplier relationships and networks, you can identify dependencies and potential sources of disruption in the supply chain.

Take for example the case of a car manufacturer who is buying a chipset from a supplier: Using a supply chain map, the car manufacturer can get visibility into the entire supply chain by tracking the primary supplier and also the sub-suppliers who are supplying the individual microprocessor chips that are in that chipset. Now, since the car manufacturer has identified multiple qualified suppliers for the critical chipset, it might think it has backups in case of disruption. But if all of these chipset suppliers are buying a specific component chip from the same sub-supplier who is manufacturing the chip, then that is not a true backup. The upstream sub-supplier is single point of failure in that supply chain. This is an example of the type of insight that a supply chain map can provide.

A supply chain map can help organizations identify and onboard multiple suppliers for critical items to ensure reliability, and also consolidate and reduce the number of alternate suppliers for less-critical items to negotiate lower rates for a larger order.

The supply chain map can help in various other cases too. For example, it can help to:

- Optimize the distance and number of hops in the supply chain

- Provide earlier predictions of disruptions in the supply chain, by identifying disruptions in upstream suppliers and manufacturers

- Plan near-shoring of operations

- Ensure that natural disaster and lockdowns in a certain region do not have a global impact

Developing a supply chain map could be a truly eye-opening exercise for organizations that haven’t previously had any level of visibility into their end-to-end supply chain.

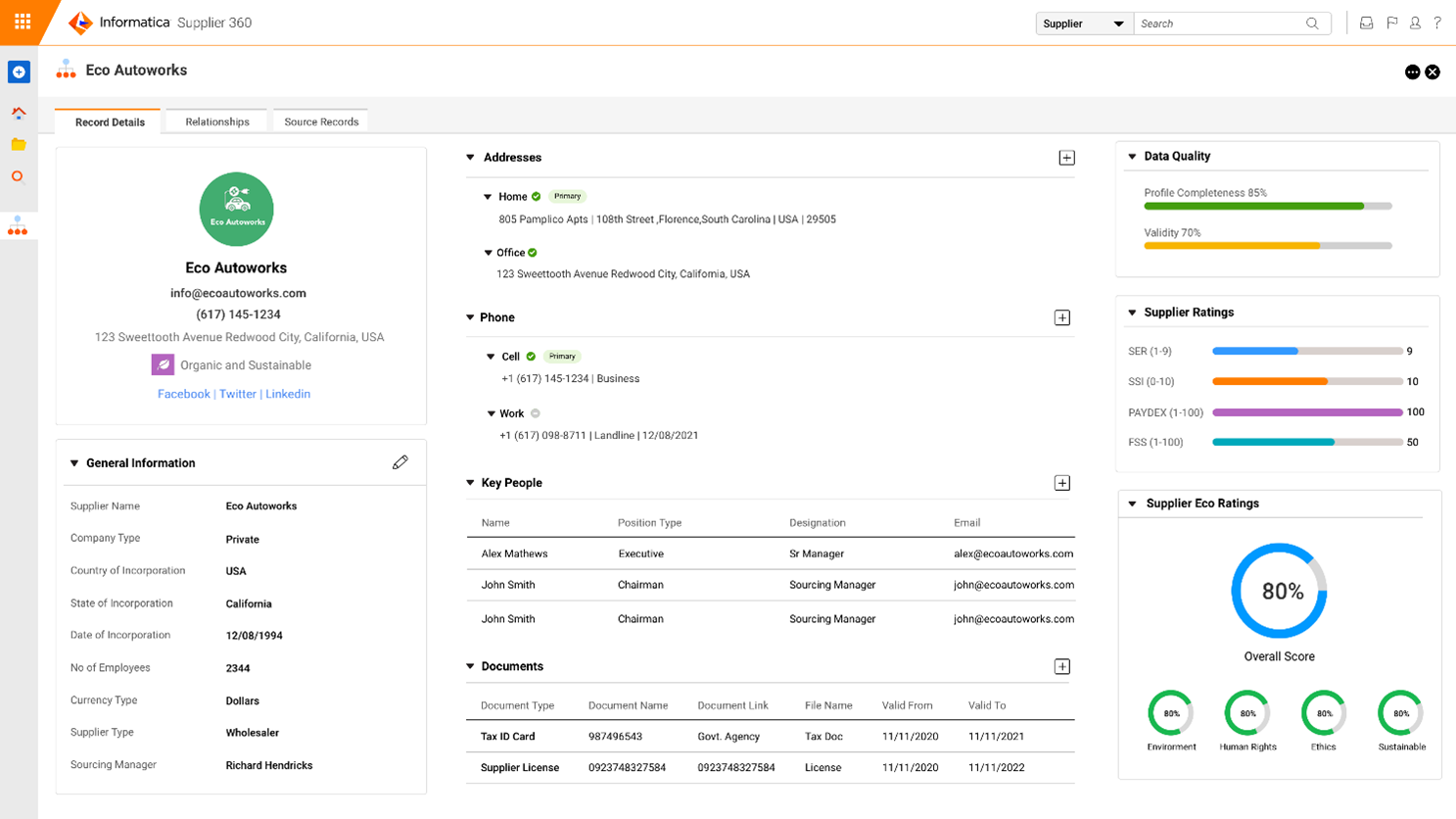

Informatica Supplier 360 enables the management of supplier and supplier relationship information, and centrally manages supplier information for a sustainable, transparent, and trusted supplier experience. It can help to:

- Improve visibility across the end-to-end supply chain

- Monitor supplier risk, compliance, and performance

- Improve visibility across the supplier network, and monitor supplier risk, compliance, and performance

- Reduce operational and procurement costs

- Feed operational and analytical applications with trusted supplier data for better planning and forecasting

- Streamline onboarding of new suppliers and products

- Improve self-service access, standardization, and automation

Having accurate and up-to-date information about strategic suppliers can be crucial to developing closer relationships, with better lines of communication and collaboration. It will help organizations come out of the pandemic with greater resilience and efficiency and ensure that they are better positioned to adapt to any future disruption.

Watch our on-demand webinar, Mastering the Complexity of Supplier Data, to learn why supplier relationship management is more important than ever.

References: https://supplychaindigital.com/procurement/visibility-beyond-tier-one-suppliers-hampering-cpos-study-reveals