How You Can Solve 5 of the Most Painful Supplier Information Management Challenges

Whether you’re talking to supply chain executives in manufacturing, in distribution, or in retail, the pain points are the same: If they’re sourcing products or services from multiple vendors, they must address some or all of these five challenges to supplier information management.

Recognize any of these? These are the five major challenges to supplier information management

Recognize any of these? These are the five major challenges to supplier information management

- No trusted view: Supply chain executives struggle to get a trusted view of all their suppliers across the enterprise. This challenge makes it tough to access all supplier information.

- Operational Inefficiencies: The current method of managing suppliers and their data is often ineffective, accompanied by a lot of redundant workload and manual processes.

- High Supplier Management Costs: This challenge increases the costs related to supplier management while it also challenges procurement (for example, when it comes to negotiating corporate discounts).

- Slow time to market is another critical challenge to efficiency and profitability. For example, the onboarding of a supplier may take months, which can delay the time to market for new offerings or products.

- Supplier Risk & Compliance: And last but not least, the ability to assess the supplier‘s risk and compliance or how they are performing is an ongoing pain point for some supply chain executives.

Taking a 360° Approach to Supplier Information Management

Managing supplier information with a 360° view is more than a methodology or technology solution. It’s a discipline, a process, and a cultural mindset that helps you do five important things:

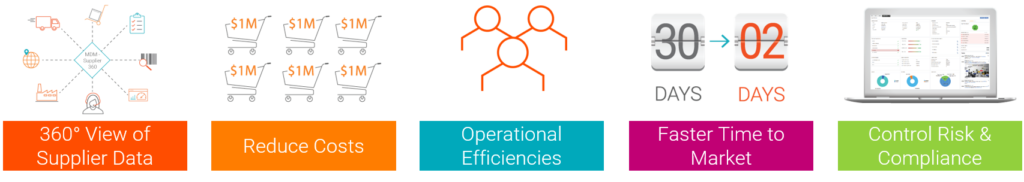

Benefits of 360° Supplier Information Management

Benefits of 360° Supplier Information Management

- 360° View of Supplier Data: By centrally managing governed and relevant supplier data across the entire business, supplier management can access a 360 view of all supplier data and gain a better understanding of all supplier relationships.

- Reduce Costs: Creating a holistic, trusted, single view of suppliers that’s available to all buying teams and applications significantly cuts supplier information management costs. Some companies save millions of dollars per year just by streamlining and automating their supplier management, and procurement and sourcing teams gain visibility to the total spend per supplier. Based on this knowledge, they can negotiate more favorable corporate discounts, pricing and payment terms to further reduce sourcing costs.

- Operational Efficiencies: With role- and task-based workflows, all departments involved in supplier management can collaborate more Supplier management and supply chain teams can streamline the way they manage the suppliers’ lifecycles, and easily monitor your suppliers’ performance, and get the answers to supply chain questions like these: “Do they deliver on time?” “Is this the right quality and quantity?”

- Faster Time to Market: By automating processes, companies can significantly increase their agility and speed up time to market, for example, reducing the time it takes to onboard a supplier from weeks to days.

- Control Risk and Compliance: By fueling all supplier-facing applications, business intelligence tools, and analytics programs with trusted, governed, up-to-date supplier data, finance, legal, and supplier relationship management teams can more easily monitor and analyze their suppliers’ risk and compliance.

360° Supplier Information Management is about uniting, cleaning, mastering, and synchronizing all of your supplier data under a single, rigorous governance regime. And it’s about streamlining and innovating the way your business collaborates with a 360° view of all supplier data. To learn more, join the webinar “What’s New in Informatica MDM – Supplier 360”.

360° Supplier Information Management is about uniting, cleaning, mastering, and synchronizing all of your supplier data under a single, rigorous governance regime. And it’s about streamlining and innovating the way your business collaborates with a 360° view of all supplier data. To learn more, join the webinar “What’s New in Informatica MDM – Supplier 360”.